1500W Water-Cooled Laser Welding Machine -In Stock, deliver in 3 days | Last 2 sets!

CAD

$ 34,000.00 & Free Shipping

- Welding Capacity: 4.5mm

- Continuous light out over 4 hours

- Unique Air Cooled Fiber Laser Technology

- 1500 Watt

- 32.52*17.074*26.44in

826*433.5*671.5mm - Ergonomic Laser head

- 220V 1 Phase

- 10m Cable

- Weld/Clean/Seam cleaning

- Separate wire feeder included

Description

Water Cooled Fiber Laser Welding Machine

DenaliWeld delivers precision, power, and innovation with our water-cooled fiber laser welding machines. As a proud employee-owned company, we are committed to providing cutting-edge technology and exceptional reliability.

- High Power Output: Supports up to 3000Wof continuous laser output, ensuring consistent and efficient performance across a range of applications.

- Reliable Operation in Extreme Conditions: Designed for continuous use, with reliable performance in environments ranging from -10°C to 40°C (14°F to 104°F).

- Modular Chiller System: Water-cooled with a modular design for easy maintenance and repair, ensuring minimal downtime and optimal cooling.

- Compact & Lightweight: Engineered for portability, it is the smallestand lightest machine in its class without compromising power.

- 3-in-1 Versatility: Combines welding, cleaning, and seam treatment functions in a single machine, providing multi-purpose functionality.

- User-Friendly Controls: Pre-set parametersenable one-click operation, reducing setup time and enhancing ease of use.

- Welding Data Acquisition System: Tracks operation metrics and cost calculations for better process monitoring and efficiency management.

- Automation Ready: Seamlessly switch to cobotor robotic welding with a single click using DENALIWELD ROBOX™, enabling automated precision welding.

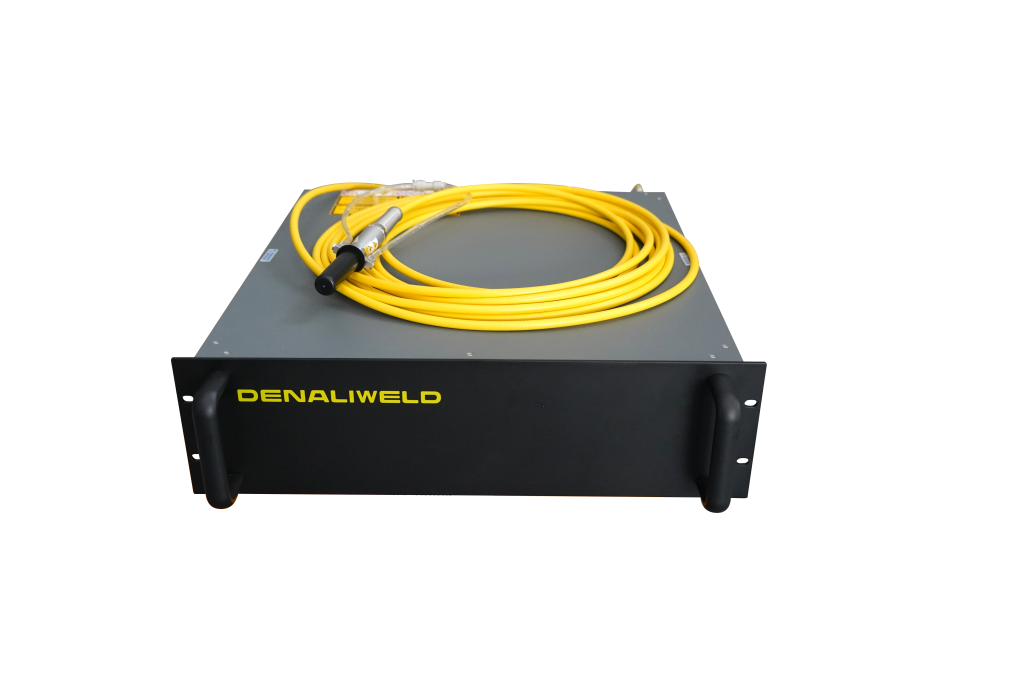

DenaliWeld Laser Source

Built for precision, power, and reliability, the DenaliWeld Laser Source delivers consistent performance across a range of industrial applications, from robotic to hybrid welding.

- Accurate, Full-Power Output: Provides precise, stable laser delivery, ensuring full power output for superior weld quality.

- Compact & Reliable Design: Designed for continuous operationin demanding environments, with reliable performance from -10°C to 40°C (14°F to 104°F).

- Advanced Laser Control System: Independently designed by DenaliWeld, our system delivers a smooth output curve, resulting in cleaner welds and greater consistency.

- High-Power Capability:

- Up to 8000Woutput for robotic welding, providing speed and precision for automated systems.

- Up to 20000Woutput for hybrid welding, delivering unmatched power for high-performance industrial applications.

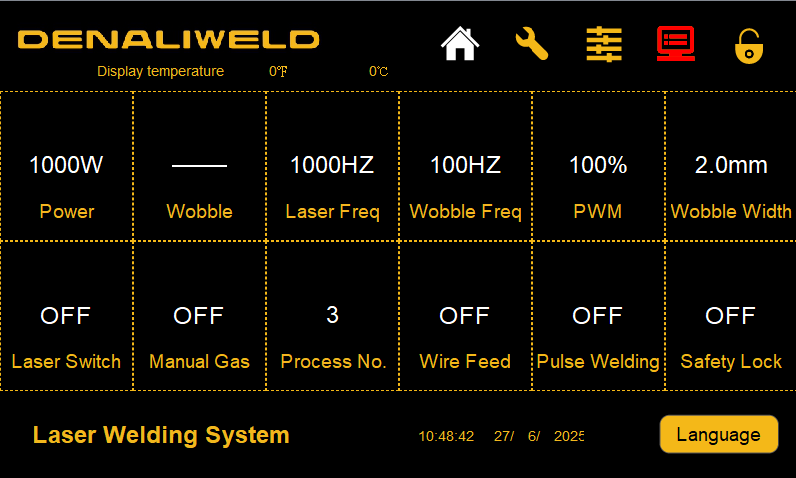

DenaliWeld Welding Control System

- Intuitive Controls: All parameters can be quickly adjusted, allowing for seamless operation and faster setup.

- Flexible Laser Positioning: Effortlessly adjust the laser position without worrying about laser deviation, ensuring precision every time.

- Advanced Safety Features: Built-in safety settingsprovide enhanced protection for both users and observers, ensuring a safer working environment.

- One-Click Welding: Select from accurate preset parameters with a simple click to start welding, improving efficiency and reducing setup time.

DenaliWeld Laser Welding Head

The DenaliWeld Laser Welding Head is designed for versatility, precision, and operator convenience, offering advanced functionality for demanding industrial applications.

- 3-in-1 Multifunctional Design: Integrates welding, remote cleaning, and seam cleaningcapabilities into a single laser head, enhancing efficiency and operational flexibility.

- Intuitive Status Display: Equipped with indicator lights for real-time monitoring, allowing operators to easily track the machine’s status and performance.

- Advanced water-Cooled System: ensures stable operation for up to four hours without overheating, as verified by test records.

- Ergonomic Design: An ergonomically designed welding machine is available with a physical safety off button, allowing for quick start/stop functionality—even while wearing welding gloves.

DenaliWeld Water Chiller

Engineered for efficiency, reliability, and sustainability, the DenaliWeld Water Chiller provides superior cooling performance to support long-term laser operation.

- Modular Design for Easy Maintenance: Built with independent modules, allowing for quick maintenance and hassle-free replacement, minimizing downtime.

- Optimized Cooling Efficiency: Designed with precise cooling capacity calculations, delivering maximum cooling performancewhile maintaining minimal power consumption, ensuring stable operation during continuous use.

- Eco-Friendly Refrigerant: Utilizes R410a refrigerant, which complies with environmental standards, ensuring sustainableand responsible

The Key of Cooling

At DenaliWeld, we use an advanced Copper + Aluminum heat exchanging system to provide superior cooling performance. Unlike the micro-tube exchangers commonly found in 99% of coolers on the market, our system delivers much more reliable and efficient cooling, ensuring consistent and optimal temperatures for your laser equipment. This results in longer operational life, enhanced performance, and increased overall efficiency.

DenaliWeld Wire Feeder

Designed for precision and ease of use, the DenaliWeld Wire Feeder seamlessly integrates with your welding system to deliver consistent performance.

- Enhanced Wire Capacity: The newly designed system supports wire feeding up to 2mm (5/64), accommodating a wider range of welding applications.

- Double Wire Feeding: Offers dual-wire feeding capability, increasing efficiency and flexibility for complex welding tasks.

- Seamless Integration: Specifically designed to complement the DenaliWeld laser welding machine, ensuring smooth operation and optimal performance.

- User-Friendly Operation: Equipped with a physical control buttonfor easy operation, even while wearing welding gloves—ensuring quick adjustments and enhanced convenience.

| Laser Power | 1500W | 2000W | 3000W |

| Operating System | 3-in-1 / Cleaning | 3-in-1 / Cleaning | 3-in-1 / Cleaning |

| Laser Wavelength | 1060-1100 nm | 1060-1100 nm | 1060-1100 nm |

| Fiber Length | Approx. 10 m (32.8 ft) | Approx. 10 m (32.8 ft) | Approx. 10 m (32.8 ft) |

| Operating Mode | Continuous/Modulated | Continuous/Modulated | Continuous/Modulated |

| Oscillation Operation Mode | Spot, Line | Spot, Line | Spot, Line |

| Positioning | Laser red dot | Laser red dot | Laser red dot |

| Gas flow rate | 10-15L/min | 10-15L/min | 10-15L/min |

| Voltage | AC208V | AC208V | AC480V |

| Power Consumption | 7kW | 9kW | 11kW |

| Frequency | 50/60 Hz | 50/60 Hz | 50/60 Hz |

| Current | 32A/19A | 40A/24A | 29A |

| Focus Lenght | 150mm | 150mm | 150mm |

| Welding Speed | 0-95cm/min (0-37.4 in/min) | 0-105cm/min (0-41.3 in/min) | 0-105cm/min (0-41.3 in/min) |

| Cooling System | Water cooling | ||

| Laser Protecion Method | laser beam lock + security lock + safety button | ||

| Touch Panel | Monitor + PLC | ||

| Wire Feeder | Single/Double Motor Automatic | Single/Double Motor Automatic | Single/Double Motor Automatic |

| Wire Diameter in Automatic Mode | 0.8 mm, 1.0 mm, 1.2 mm, 1.6 mm, 2.0 mm (0.030", 0.035", 0.045", 1/16", 5/64") | ||

| Machine Weight | Approx. 80kg/176bl | Approx. 85kg/187bl | Approx. 90kg/198bl |

| Machine Measurements | Height 810mm, Width 580mm, Length 1170mm | Height 794mm, Width 497mm, Length 984mm | Height 1000mm, Width 720mm, Length 1370mm |

| 3-in-1 Laser Head Weight | Approx. 900g/1.98lb | ||

| 3-in-1 Laser Head Size | L: 273.38mm, W: 36.5mm, H: 168.57mm | ||

| remark: | cleaning function Max. 2kw for opertion |

Reviews

There are no reviews yet.